Our Technology

Nanofibers

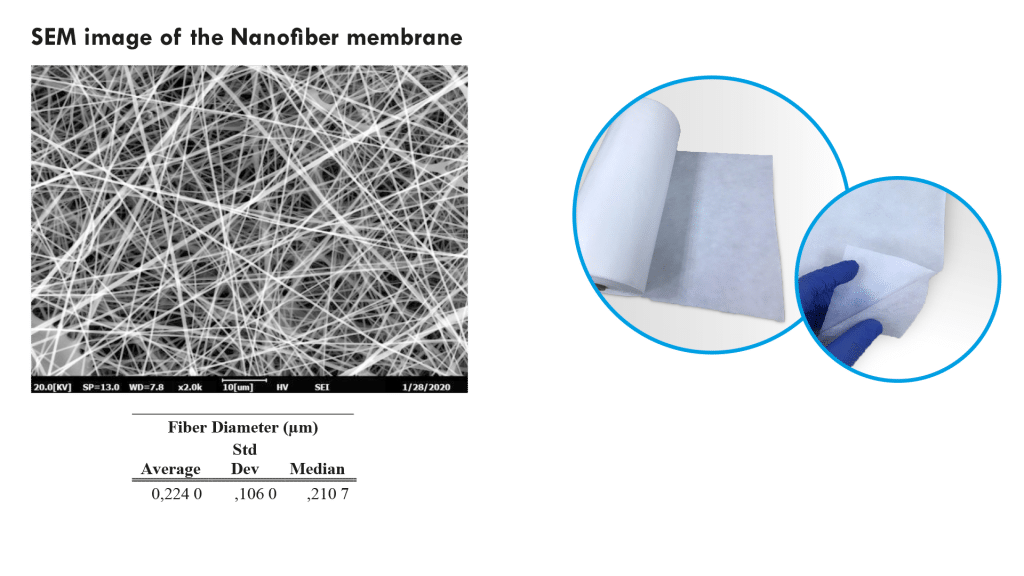

Nanofibers are one of the pioneering nanostructures due to their novel properties like extreme high surface area, low density, high pore volume, controllable mechanical properties as opposed to many other conventional bulk materials. They also represent a new generation of reinforcement for the fabrication of well-tailored unique nanocomposites. There are extensive variety and critical areas of applications of nanofibers such as healthcare, energy, catalysis, sensors, bioengineering and environmental technology to name a few.

Nano95™ and Nano99™ Filtration Media

FILTRATION EFFICIENCY : +95% / +99%

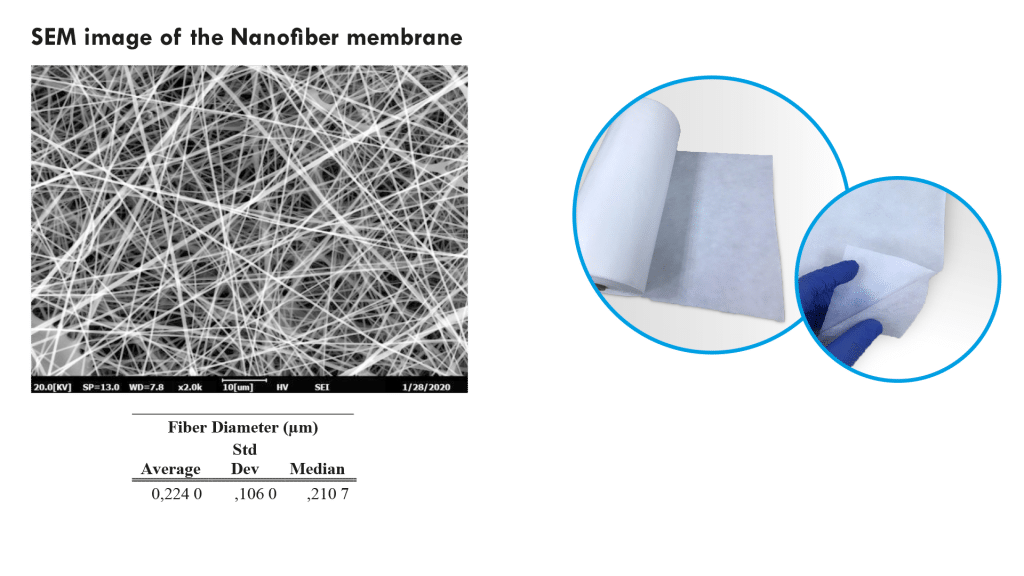

Outer layer: PET Spunbond 35 g/m2

Inner layer: Nanofibers layer of polymer PVDF 0.6/0.8 g/m2

Outer layer: PET Spunbond 35 g/m2

Can be produced with specific properties like hydrophobic, antibacterial, different colors on demand.

Replacing Meltblown Materials

The structure of nanofiber media makes them a unique material for fine dust particles, aerosols, bacterias or viruses. Nanofiber based filters provide better filtration performance than conventional meltblown materials with a quite smaller weight per basis area.

Innovative Materials

The nanofiber membranes are considered to be the next generation filtration media, due to their high efficiency. Large corporates are looking into incorporating them in their products range.

Patented Technology

The filtration media is produced using a patented novel technology “Hybrid Electrospinning”.

TECHNICAL FEATURES

• Low-pressure drop for better breathability.

• Enables capturing inhaled particulates such as bacterias and viruses.

• Designed to provide protection of 96% and 99% filtration efficiency.

• High efficient mechanical filtration. No filtration performance loss according to change of electrostatic properties.

Nanofiber Coated Media. New Generation of Filter Media?

Experts advocate that surgical masks cannot sufficiently protect against viruses, and it will be more efficient to choose masks known as N95. Although N95 masks have high filtration efficiency, they are thicker than surgery masks and rather uncomfortable for long-term use in daily life. These masks make breathing difficult during use, and users experience serious problems due to the increase in temperature and humidity between the face and the mask tissue.

When all these experiences are evaluated, it becomes necessary to develop a filter media that will provide the necessary protection against viral risks and which is comfortable enough for daily use. At this point, the application of nanofiber technology, which offers unique solutions in many different application areas including filtration, comes to mind as a solution based on solid scientific data.

Filters made up of Nano-sized fibers have a 99.9% efficiency in trumping viruses and bacteria and are very comfortable in terms of use. With a thin non-woven fabric, the spunbond fabric consist of a very low weight nanofiber coating that fully meets user expectations with its flexible structure and morphology that easily passes moisture.